Traditional fuels for generation of electrical energy include burning of fossil fuels, waste, biomass, and nuclear energy. Their obvious problem is environmental cost. The footprint is high for fossil fuels, mainly as carbon releases into the atmosphere. There are also issues with releases of heavy metals and toxicity of ashes. Waste and biomass are considered renewable sources, but come with higher content of toxic gasses, mainly NOx in the exhaust. Nuclear fuel does not normally have issues with atmospheric discharges and its energy density is incomparably higher than other fuels, but waste storage is not an easily solved problem due to both technological and social circumstances.

Their strong point is availability: they can work exactly as much as the network needs to up to the top power availability, and do not depend on current weather conditions or time of day. Geographical location is of low importance, as both fossil fuels and uranium are relatively easily transported and comparatively little demineralised water is needed for steam as it is constantly recycled.

Because of the above explained facts the constant safety program and operability maintenance is crucial and extremely important.

The basic protection for people operating and working on the platform as well as live beings in surrounding is grounding and lightning protection.

MEASUREMENTS

Metrel instruments are helpful at nearly any stage of operation or location within the power plant. To test the lightning protection on the tall buildings and exposed parts of construction most of existing measuring methods are supported in MI 3290 Earth analyser where RE at frequency 55 Hz of parallel groundings sweep to RE at 15 kHz of local grounding could be expressed on the same graph on the instrument’s screen.

Another great method supported in MI 3290 Earth analyser is 10/350 Lightning strike pulse measurement where additional evaluation of local grounding could be established and compared to low frequency RE result. This method would be recommended in areas where sensitive electronic devices could be exposed in case of bad grounding. Lightning strike can jump into the building instead discharge to ground where ratio of impedances is greater than 2:

Z @PULSE / Z@LOW Freq. > 2 / 1

The fastest method to evaluate connected loops of any Faraday cage protection in the platform would be 2 clamps method supported by high efficient battery operated industrial tester like MI 3155.

All the loops shall be tested with this simple method. But many times and in many cases on thermal energy power plants the metal straps are replaced by heavy and tick construction parts where classic approach has its limitation in size of 52 mm of clams aperture on one side and the current generation ability.

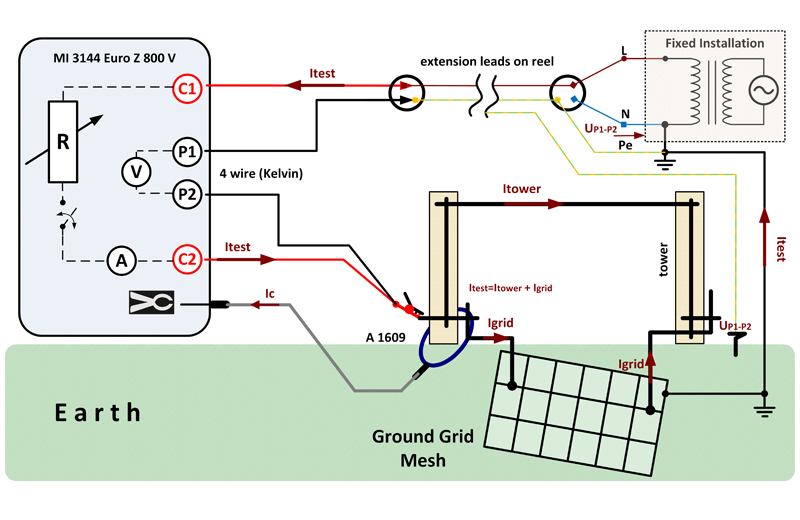

Testing of any platform with heavy metal construction need to be tested with high current of several 100 A where the portion of the current generated shall be measured through partial legs to ground. The method is known as Single Clamp method. The most convenient clamps available are large 90 cm long Rogowski Flex clamps A 1609.

The measuring method is supported in best combination of MI 3155 tester with high current generating through the MI 3144. This set can generate above 300 A current to the construction. Time limited current pulses take care of safety for people in surrounding.

Measurement is performed within a half-period and therefore the safety condition is fulfilled even during high current pulse with up to several hundred volts. Synchronized measuring method and a higher current amplitude improves the immunity against voltage noise.

Testing of grounding in surronding of the platform shall be inspected periodicaly. The Contact voltages, Step voltages and Touch voltages shall be measured and proportionaly recalculated to the situation of lightning strike and ground fault (HV / MV or LV). The tripout time adjusted to the platform shall be considered to evaluate all safety aspects, usualy between 200 to 500 ms.

Step & Contact System MI 3295 with several independent sensitive voltmeters MI 3295M can support such a testing where several groups can work simultaneously around energetic power platform. When the generator is running synchronized many voltmeters as needed to do all the necessary measurement all around the tested area. All conductive parts, rails, pipes, fences, etc could be potentially dangerous and must be inspected.

Example of step voltage testing on separated concrete plates where using of 2 x Cooper plates of 30 kg.

Example of touch voltage testing at 1m distance from the metal construction using 2 x 25 kg plates.