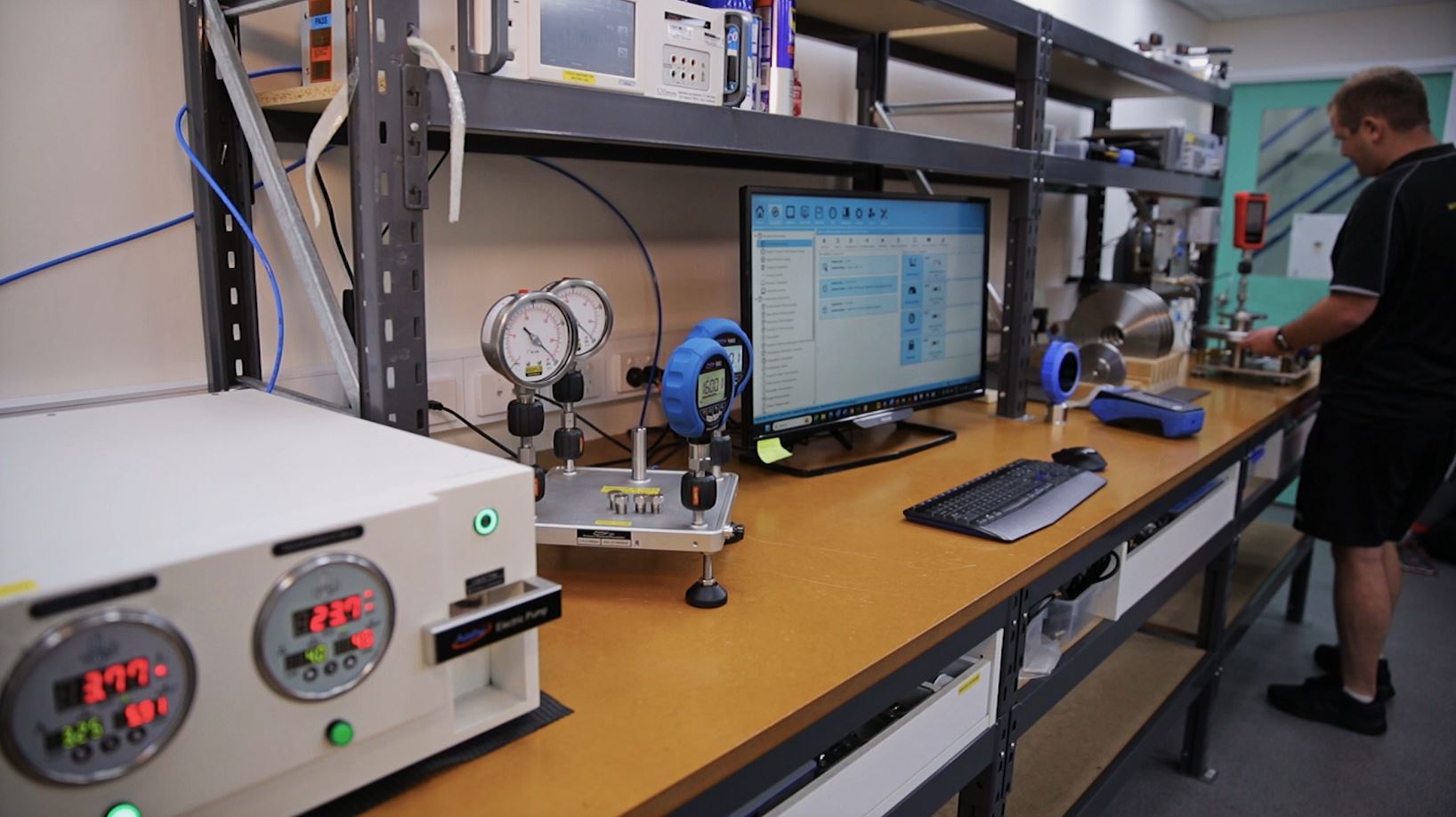

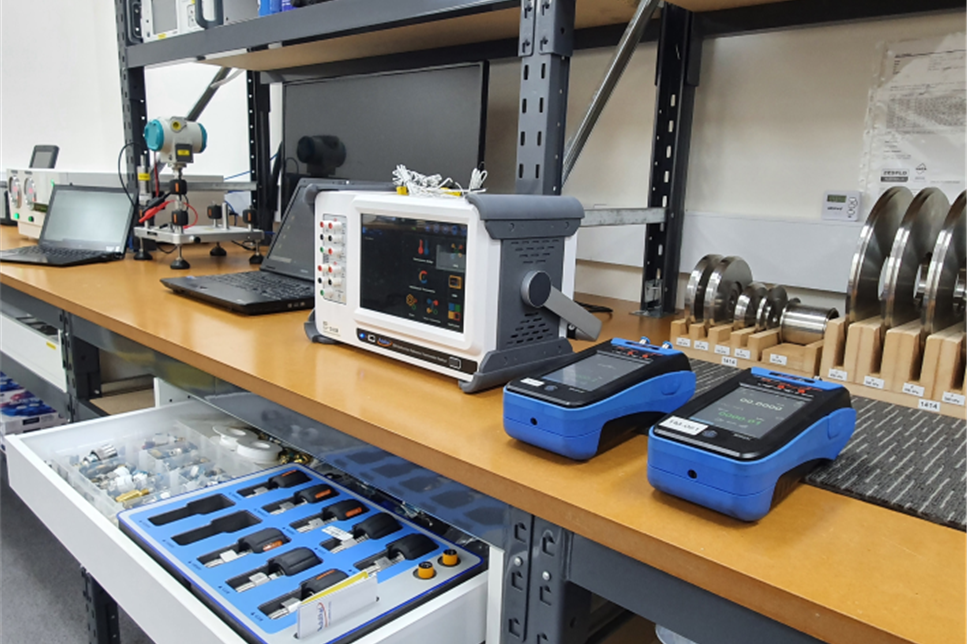

Experts in NATA accredited analogue pressure gauge calibration

If you need analogue pressure gauge calibration, get in touch with us at Zedflo. With over 40+ years of industry experience, our team is adept at ensuring your instrument measures correctly and accurately.

To ensure your pressure gauge functions properly, provides accurate readings, and maintains compliance with manufacturer and Australian standards, it is generally recommended for analogue pressure gauges to be calibrated every 12 months. Read more on calibration interval

We can test from ultra-low DP devices up to 4200 bar, and 0.009% uncertainty*. With the widest pressure calibration scope in WA, and among the best in Australia, we can provide a NATA accredited calibration service for virtually any type of analogue pressure gauge model in use in Australia, including gauge, vaccum, compound, and absolute ranges.

*See our NATA scope here for full details.

No booking required

There’s no need to arrange an appointment in advance. Simply post or drop off your instrument whenever it’s convenient for you during business hours. Our efficient process ensures instruments are calibrated as soon as we can based on our current waiting list (Most cases can expect a turnaround time of between 3 and 7 days). For urgent cases, expedited services are also available for an additional fee.

Rest assured, your equipment will be handled with precision and care from start to finish, backed by our industry-leading expertise and NATA-accredited calibration standards.