More information on Pressure Switch Calibration

At Zedflo, we provide comprehensive pressure switch calibration services, enhancing the accuracy and reliability of these crucial industry components to have the electrical switch function programmed, adjusted, or configured to operate correctly.

What is Pressure Switch Calibration?

Pressure switch calibration is a critical maintenance task that involves testing and adjusting a pressure switch to its maximum rated pressure value, as well as introducing a slowly changing pressure ramp to from/to maximum pressure / minimum pressure, and to the switch set point/s, using a falling pressure or rising pressure profile depending on the switch type. A calibrator monitors the normally open switch terminals for change, once the switch status has changed pressure slowly can be increased or decreased to determine the maximum pressure differential or ‘deadband’. Calibration is essential for accurate detection of the pressure at which the switch activates. This is to ensure it the switch closes and functions accurately and reliably. This procedure is vital for systems that depend on precise pressure measurements to manage fluids in various industrial applications. such as as a safety pressure switch, a safety alarm level, general industrial switches, shop air supply, or general safety switches.

Why Calibrate Pressure Switches?

Pressure switch calibration is essential for maintaining safety, additionally it helps to keep the process which the pressure switch is used in, whether you have safety switches or it’s used in a pressure line or process, pressure switches can be crucial to avoiding over pressure or low pressure situations or overloading a systems maximum rating. Many switches are used as a ‘limit switch’ and as such often switches stay static and can drift out of spec just from sitting idle. Proper calibration ensures consistent quality in measuring with suitable pressure applied, our systems accurately capture switch trip and switch return, as well as the maximum dead band, and helps your system to meet stringent industry standards and regulations. Capturing the input pressure automatically during switch calibration eliminates delays and inaccuracies by recording the pressure at the very moment the switch operates, allowing for precise measurements even when the transition occurs between two readings.

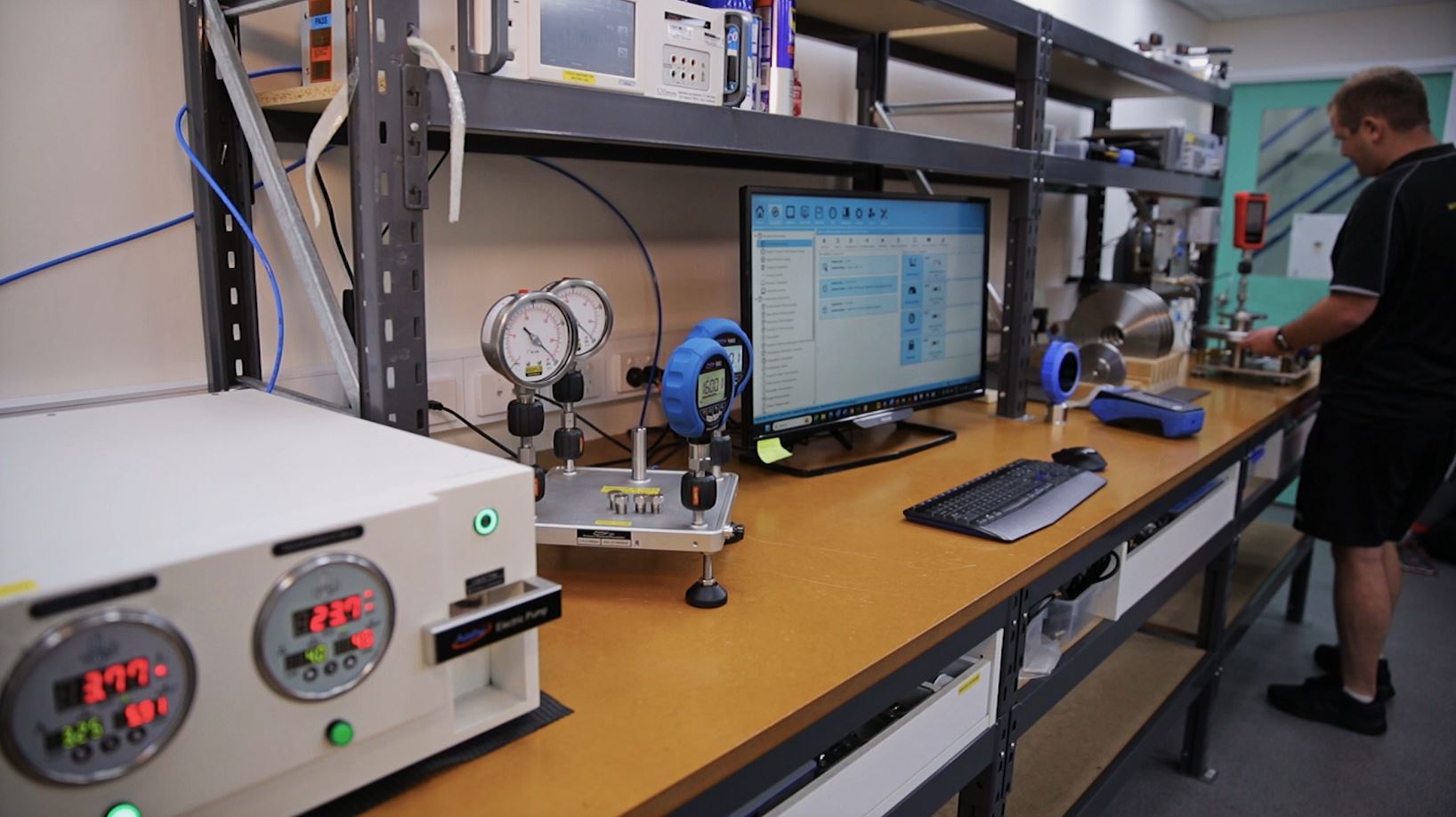

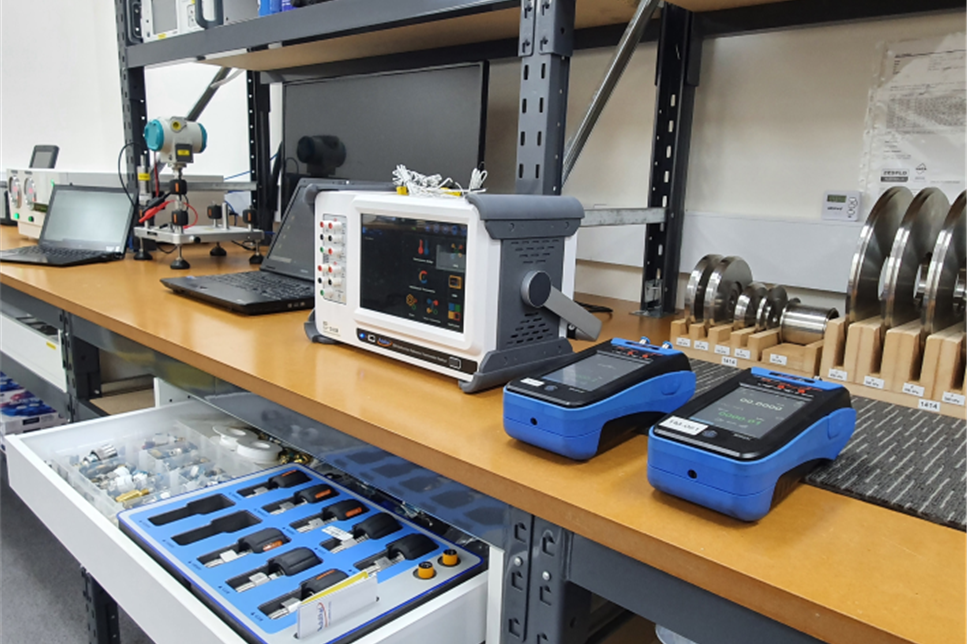

Our Calibration Procedure

Our skilled technicians perform a detailed calibration process for pressure switches to ensure the trigger level is corrected detected when the switch opens or if the switch changed continuity. That begins with verifying the current settings and performance of the electrical switch function and switch terminals of your pressure switch against established standards. A changing pressure ramp is used during the calibration process to ensure accurate detection of the pressure point at which the switch activates. Using a precise pressure controller as a pressure source, we ensure accurate pressure adjustments to capture the operational points accurately. Any deviations from expected performance are corrected to align the switch output with precise specifications, and we provide detailed records of all switch changes. Several passes may be carried out to find operation points depending on the switch type, from the very first point that a switch ‘trips’ to the set point it resets.

The Importance of Regular Calibration

Regular calibration of switches can help to extend the life of the equipment. A slow pressure ramp is crucial during calibration as it allows for accurate detection of the switch’s operating points by ensuring gradual pressure changes. It enhances efficiency and process quality, preventing costly downtime and repairs. This is particularly critical in industries where precision in pressure measurement is directly linked to safety and quality.

Explore Zedflo’s Pressure Switch Range

Zedflo offers an extensive range of industrial Neo-Dyn pressure switches to industries across Australia suitable for various applications, including hazardous environments and high-vibration settings. Some of our switches are normally open, meaning they remain open when no pressure is applied and closed when sufficient pressure is applied. Our inventory includes compact and general-purpose switches that are perfect for a variety of applications. We have a variety of high impulse and differential switches designed for high-stress environments, as well as dry and wet switches. Additionally, we supply vacuum and ultra-low switches that come with weatherproof and explosion-proof options. We also provide special application switches designed for the stringent sanitary conditions required in the food and beverage industry.

Contact Zedflo for Expert Guidance

For those looking for expert advice on selecting and maintaining the right pressure switch, or need for pressure switch calibration, Zedflo is here to help. Our team is ready to assist you in ensuring process quality enhancing your safety and your operational efficiency with high-quality services, tailored to your specific requirements. To learn more about how our own switch calibration services can benefit your operations, visit us at Unit 3, 115 Excellence Drive, Wangara, WA 6065, call us at (08) 9302 1266, or email sales@zedflo.com.au.

Other Frequently Asked Questions (FAQs)

Can you calibrate a pressure switch?

Yes, calibrating a pressure switch is a crucial maintenance task. We are equipped to precisely calibrate most pressure switches in the Australian market. Calibrating a pressure switch ensures the switch operates more accurately and reliably. At Zedflo, we specialise in calibrating switches to meet precise operational standards.

How do you perform pressure calibration?

Pressure calibration involves several steps including verifying the switch’s against known standards and adjusting the switch to detect and correct errors. It is crucial to provide a slowly changing pressure ramp during the calibration process to allow for accurate detection of the pressure point at which the switch activates. During calibration, if there are any discrepancies to the device under test, we will document the entire process for compliance and quality assurance purposes. Our technicians use calibrated instruments to make switch changes and ensure accuracy during this process.

Calibration of specialty switches

We do have the capability to calibrate most switches in the Australian market, if you have some unique instrument or device such as an atmospheric pressure sensor, safety switch, wet switch, dry switch, or most types in use in the process industry

How can I test a pressure switch?

If you are looking to perform your own test or calibration, you could use a calibration hand pump and a calibration reference test gauge or calibrator with a pressure reading. An automatic calibrator like the Additel ADT673 can connect to the pressure switch contacts and utilising applied pressure can monitor the switch set point and reset point as it measures pressure. You can use equipment as simple as a pump and a gauge, to input pressure manually to ensure the switch responds correctly to the setpoint pressure changes, however a calibrator can help you to perform multiple passes to determine the maximum dead band in either failling pressure or rising pressure as it monitors for any status change in the output state which is captured automatically and logged.

How do you calibrate a switch?

Calibrating a switch (specifically a pressure switch) involves setting the switch to its operational specifications. A changing pressure ramp is crucial during the calibration process as it allows for accurate detection of the pressure point at which the switch activates. This includes determining if the switch is normally open or normally closed, adjusting the two setpoint pressure points where the switch activates or deactivates, ensuring these reset pressure points are accurate under normal operating conditions.

Can a pressure switch be adjusted?

Yes, most switches can be adjusted. Adjustment typically involves setting the activation set point, adding pressure on the setpoint, and deactivating pressure points according to the specific needs of the application or to restore accuracy. Some models have external adjustment and some have a tamper proof adjustment which is a bit more complex as it will often involve removing it from the pressure source for each adjustment step.

How do I know if my pressure switch is bad?

Signs that a pressure switch may be failing include erratic operation, failure to activate or deactivate at the correct pressure levels, no response at any pressure drop or all, rising pressure or falling pressure from above. A delayed output, irregularities during normal usage, or inaccuracies in system pressure readings can also indicate a malfunctioning pressure switch.

Why do pressure switches fail?

Switches can fail due to several reasons, such as mechanical wear and tear, exposure to extreme conditions, contamination, or improper installation. Regular maintenance and accurate calibration of switches can help mitigate these issues.

Can a pressure switch be repaired?

In many cases, a pressure switch can be repaired, especially if the issue is related to calibration or minor mechanical problems. However, if the switch has significant damage or is very old, replacement might be more cost-effective.