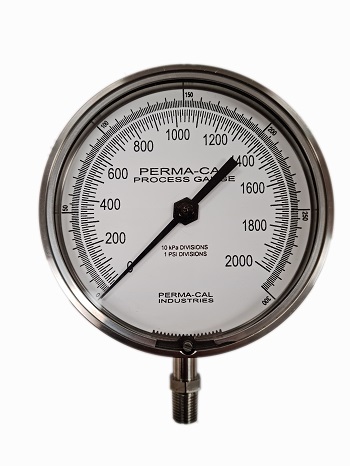

High performance pressure gauges, these bottom entry stainless steel gauges are robust and reliable designed for severe service applications

High Performance Stainless steel GAUGE, bottom ENTRY, Process Gauges

DESIGNED TO PERFORM ON ANY APPLICATION, HIGH QUALITY PERMACAL PRESSURE GAUGE

ADVANTAGES

-

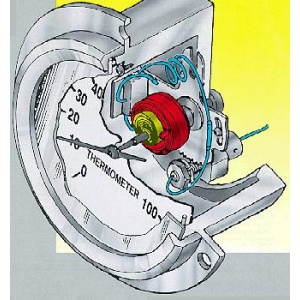

ONE MOVING PART

Unmatched vibration, pulsation and shock performance.

Helical Bourdon Tube = Gearless, Direct Drive = DURABILITY

No linkages, springs, gears, or liquid fill to wear, break or leak. Unique, internal pointer dampening reduces pointer flutter without the negative consequences of liquid fill. Sanitary environment friendly.

-

OOPS! PROOF

Proof Pressure (over-pressure) of 150% F.S. exceeds industry standards.

Survives the day to day beatings of an industrial environment in addition to the accidental drop, channel lock tap or the surprise pothole. Additionally, where vacuum can sometimes damage a C-tube gauge, Direct Drive is unaffected.

-

AEROSPACE QUALITY | MILITARY TRUSTED

Direct Drive is demanded on critical applications.

The same military grade Direct Drive technology used in our Aerospace and Military designs, is used in our industrial gauges for commercial applications. Ideal for land, air, sea, and space.

The U.S. Military recognizes the durability advantages Direct Drive provides and requires it on their most demanding applications.

-

TEMPERATURE HERO

Trusted in extremes from -65°F up to 600°F media. Accuracy is 25% less affected by temperature fluctuations.

Inconel Elastic Element = Low Coefficient of Thermal Expansion

Inconel in combination with a low internal volume means that the impact of temperature on accuracy is significantly less than competitors using a Stainless Steel Bourdon Tube. High-Temp solutions available which bring operating temperatures up to 400°F Ambient / 600°F Media.

-

USA PARTS, USA MADE, USA OWNED

Manufactured in Minden, NV using only American made parts. Manufacturing processes not completed in house are outsourced to support local small businesses.

-

LIFETIME LIMITED WARRANTY

Lifetime warranty that the Bourdon tube will not malfunction due to wear.

1 year from delivery or 18 months from date of manufacture against defects in materials and workmanship.